Technology Platform

Arctic Bioscience uses proprietary technology developed by our in-house science and technology team in Ørsta to manufacture high-quality marine extracts. The extraction technique and production process utilize specialized technology to gently separate the protein and lipid fractions in the herring roe. By using this technology the product fractions are protected from being exposed to unnecessary heating and detrimental amounts of oxygen. Extensive use of high manufacturing temperatures and exposure to oxygen will lead to deterioration of the delicate natural products extracted from the roe, where the complex polar lipid fraction of the roe is particularly susceptible to degradation upon exposure to harsh manufacturing conditions.

The new state-of-the-art manufacturing facility currently being developed in Ørsta will be built around the same manufacturing principles, thus ensuring production of high-quality materials both for nutraceutical and pharmaceutical applications. The factory will have one manufacturing line operating according to cGMP, which allows for in-house API manufacture for the pharmaceutical development of our complex polar lipid APIs.

The Harvesting Process

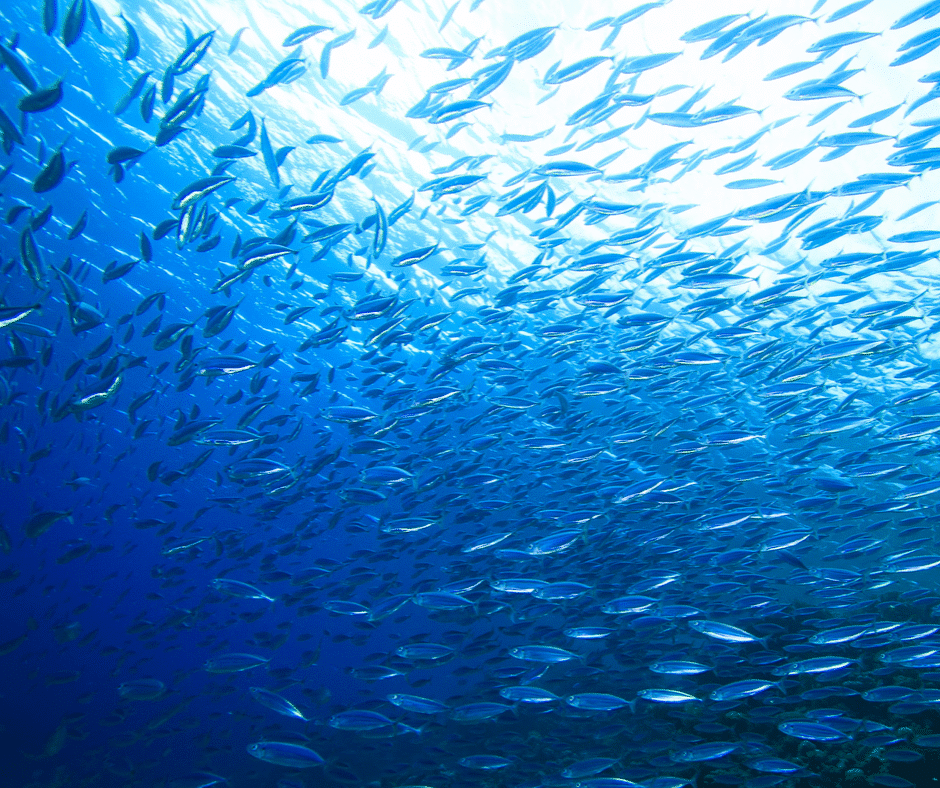

Caught On The Norwegian Coast

Norwegian Spring-Spawning Herring is the world’s largest biomass. We utilize roe from the fishing that takes place during the spawning season in February every year. The herring is caught along the Norwegian coastline.

Herring Fillets Are Produced Locally

The fishing boats arrive at the local fisheries with their harvest. Herring fillets are produced for human consumption whilst the roe is retrieved as a side-stream. Today, the roe is considered a residual material that can be utilized.

The Herring Caviar (Roe) Is Collected

During the harvesting season, we extract several hundred tons of herring roe which is frozen into blocks of 20 kilos which is stored locally. This is a gentle process that maintains the high quality of the roe.

Materials & Methods

During the harvesting season, we extract several hundred tons of herring roe which is frozen into blocks of 20 kilos which is stored locally. The team is present at the fishery throughout the harvesting season to ensure that the quality of the herring roe meets our high-quality standards. Throughout the process, samples are taken consistently to examine the size, color and water- and oil content.